Products

Qpex RTP

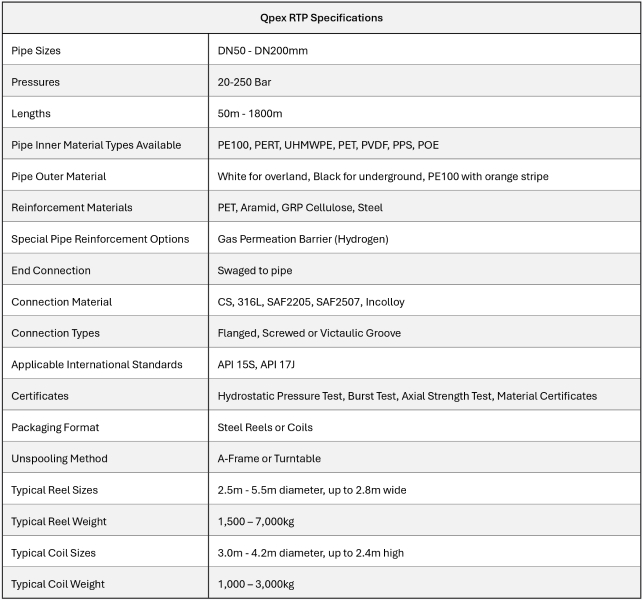

Qpex RTP – Reinforced Thermoplastic Pipe

Introduced to the Australian mining industry in 2021, Qpex RTP combines internal axial reinforcement with thermoplastic inner and outer walls, delivering exceptional strength and durability. Engineered to withstand high pressures, it is supplied in long-length reels or coils, minimising the need for joints and connections.

Suitable for both above-ground and underground applications, Qpex RTP is a proven alternative to steel and lined steel piping systems. Its unique design offers:

- Universal Corrosion Resistance – unaffected by harsh mining environments.

- High Abrasion Resistance – long service life even in demanding slurry and tailings duties.

- Low Friction Loss – smooth, easy-to-clean bore prevents scaling and reduces pumping costs.

- Fast & Simple Installation – long continuous lengths reduce welds, flanges, and downtime.

For vertical piping, the axial reinforcement delivers superior load handling, making it ideal for deep shaft or dewatering lines. With fewer joins, lighter handling, and rapid installation, Qpex RTP provides a high-performance, long-life solution that reduces maintenance and maximises operational efficiency.

Overland Tailings and Paste Installations

Qpex RTP features a white UV-resistant outer layer for long-term durability in harsh outdoor mining conditions. Supplied on heavy-duty steel reels, it can be easily deployed using an A-Frame, enabling rapid and controlled installation across challenging terrains.

- Rapid installation over long distances, typically 2000-3000m per day

- Less machinery and labour to install

- Flexible over ground, less preparation, no pipe support requirements

- Less joins, lowers friction loss and pump power

- Corrosion resistant and wear resistant

Qpex RTP for Vertical Mining Installations

Qpex RTP, engineered with high strength axial reinforcement, provides superior tensile capacity and stability for vertical installations. Unlike heavy, short-section steel pipes that require welding and rig-lowering, Qpex RTP is supplied in continuous lengths for safer, faster deployment in shafts, boreholes, and steep open cuts.

KEY BENEFITS

Safe and rapid installation

Simple mounting from a top bracket

No grouting required

Pipe flexibility prevents cracking from ground movement

Non-corroding

Smooth, scale free

Applications include:

- Rising mains for dewatering

- Paste down-hole piping

- Interlevel piping for paste and dewatering

- Drainage water systems

- Potable water & Process Waterfeed

- Compressed air

Qpex RTP in Underground Drives

The combination of strength, flexibility, and a non-corroding pipeline makes Qpex RTP ideal for use in underground drives. Being flexible, it can be rapidly installed, and requires no pipe alignment. Mounting close to the backs, the pipe installation is safer, with more clearance underneath for mobile equipment, which reduces the chance of damage. The pipe flexibility also reduces the need for elbows.

Qpex RTP Paste Friction Loops

Qpex RTP smooth bore high pressure pipe coils are ideal for paste friction loops. When placed underground, the ends of the coil can be connected directly to the main paste line for efficient pressure reduction without any other installation. The coiled pipe has a large bend radius, which eliminates wear issues and makes it easy to clean. Sizes range from 75-150mm ID.

Qpex TuffCore

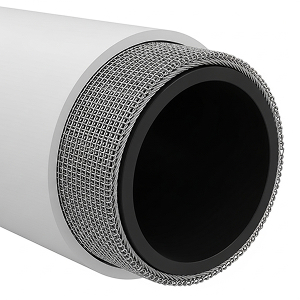

Qpex TuffCore pipe is designed with an internal wire reinforcement layer between thermoplastic inner and outer walls. This reinforcement increases the hoop stress, allowing higher ratings with less wall thickness and a smaller outside diameter, lowering material costs and plastic usage.

The inner pipe wall provides a substantial wear allowance without affecting or reducing performance, which extends the service life in abrasive applications.

The reinforcement layer controls expansion and lowers the thermal derating factor, maintaining dimensional stability and consistent performance in varying temperature conditions, making it ideal for aboveground mining installations.

Each production batch undergoes testing and verification to meet design and quality standards, including checks for dimensional accuracy, material integrity, and pressure performance. The service factor of TuffCore is more than twice that of plain HDPE, providing additional operating margin and reliability for demanding applications.

Specialised polymer options are also available for increased wear resistance, along with a wide range of connection types.

7 TuffCore Benefits vs. HDPE

- Lower thermal expansion – 80% less than HDPE.

- Performs better at temperature – pipe pressure is less affected by temperature increases.

- Higher strength and smaller wall thickness – reduced pipe size and weight for the same ID.

- Extra wear life – inbuilt wear allowance and highly wear resistant inner material options.

- Superior safety – a minimum safety factor of 3, more than twice that of HDPE.

- Lower cost and smaller environmental impact by using less plastic to produce.

- Much higher pressure options – from 12 Bar to 150 Bar.

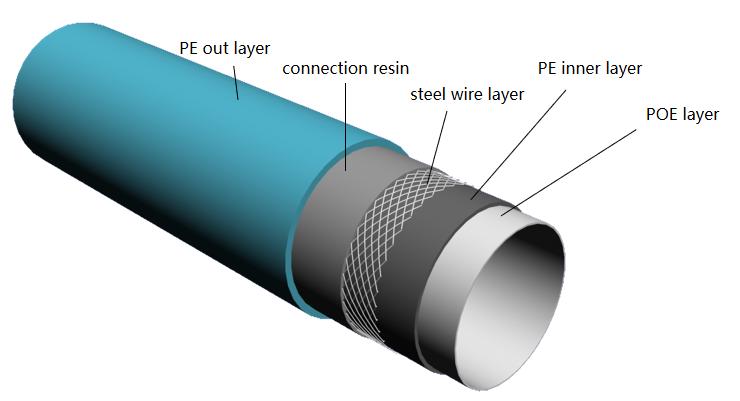

Qpex TuffCore with Wear Resistant Liners

Highly wear resistant POE and UHMWPE inner liners are available for Qpex TuffCore pipes to significantly extend the service life in abrasive slurry applications.

Our uniquely modified POE polymer (mPOE) has exceptional wear life, around 8-12 times better than HDPE.

UHMWPE liners are also highly wear resistant, and have a very low surface friction coefficient which prevents scaling. The wear life is approximately 3-4 times better than HDPE.

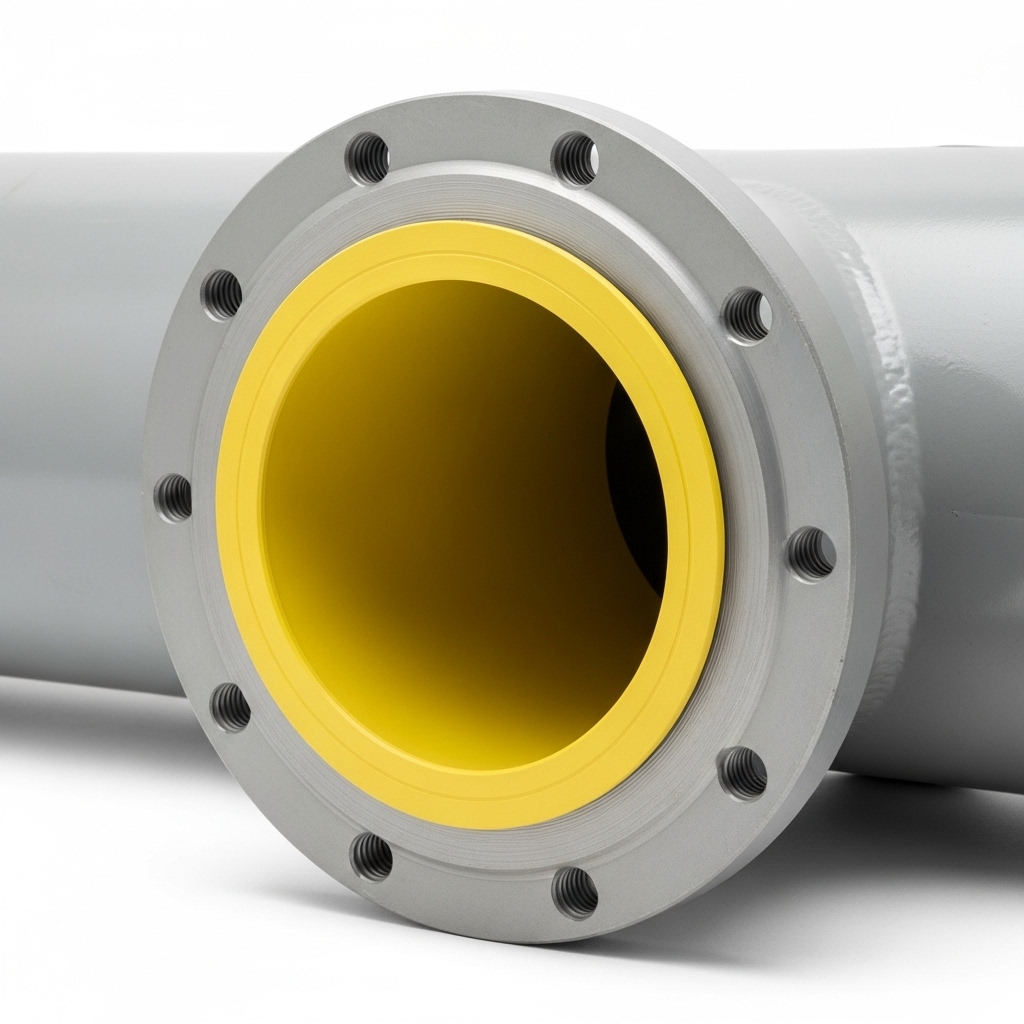

Easy Installation & Connection Options

Qpex TuffCore is available with a variety of connection types, ensuring quick and reliable installation on-site.

Flanges – Plastic

Sizes to 300mm Pressure to 20 Bar

Flanges – Steel Swaged

Sizes to 600mm Pressure to 50 Bar

EF Couplings

Sizes to 1200mm Pressure to 40 Bar

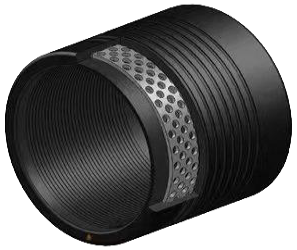

ACME Threads

Sizes to 300mm Pressure to 40 Bar

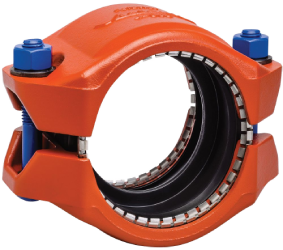

Victaulic Couplings – Plain End

Sizes to 900mm Pressure to 30 Bar

Victaulic Couplings – Groove End with Swage

Sizes to 250mm Pressure to 150 Bar

Qpex TuffCore Pipe with Coex White Outer

The coex white outer option enhances UV resistance, while minimising pipe temperature and thermal expansion. This solution is preferred for all outdoor pipe installations in mining.

Qpex TuffCore Specifications

- Pipe Sizes — DN90 – DN1200mm

- Pressures — Up to 150 Bar

- Pipe Outer — PE100

- Pipe Inner — PE100, with options for POE and UHMWPE

- Manufacturing Methods — Combined extrusion and wire overlay process

- Fluid Temperatures — -50°C to 75°C

- Connection Types — Butt Weld, EF Coupling, Flange, ACME Thread, Victaulic Coupling

- Pipe Lengths — Up to 20m long per spool

- Available Fittings — Elbows & Bends (30°, 45°, 60°, 90°), Tees/Red Tees, EF Couplings, Stub Flanges

- Certificates — Hydrostatic Pressure Test, Burst Test, Material Certificates

- Thermal Expansion Coefficient — 3.5 × 10 -5 / °C

Tailings & Dewatering Pipelines

Qpex TuffCore is the best piping design for tailings & dewatering pipelines, with a wide range of pipe sizes, materials, pressures and connection types for each application and site specific requirements.

With matching high pressure fittings including bends, elbows, tees, and knife gate valves, we provide a complete piping solution for tailings and dewatering pipeline requirements.

Qpex Ultra-High Pressure Pipes (UHP) – 100 – 150 Bar 6” & 8” Sizes

Qpex TuffCore UHP, supplied in 4”, 6” and 8” sizes is designed for high pressure dewatering and paste distribution applications in underground mining. This lightweight, corrosion proof piping has a longer wear life and is smoother than steel pipe. Qpex TuffCore UHP is supplied with Victaulic style end fittings and in lengths up to 6m, along with 3D or 5D sweep bends in 30°, 45°, 60°, and 90°.

Chemical Piping & Valves

Our lined chemical piping products, made with high-performance fluoropolymers including PTFE, PFA, FEP, ECTFE, PVDF, and thermoplastics, are completely resistant to corrosion from a full range of acids, reagents and solvents.

Our range includes:

- Spools, elbows, and reducers

- Tees and instrument tees

- Braided hose

- Acid mixers

- Tank sparges and dip tubes

- Lined or full plastic-bodied valves (valves are available in manual and actuated options)

Qpex Lined Pipe / Braided Hose Specification

- Pipe Sizes — DN15 – DN1600mm

- Pressures — Up to 50 Bar

- Standard Liners — PTFE and PFA, with optional PTFE-M, PVDF & PP

- Manufacturing Methods — ASTM certified Paste, Ram and Isostatic Moulding

- Temperatures — -150°C to 230°C

- Flange Standard — ASME B16.5 Class 150# and Class 300#

- Flange Configuration — Fixed or Rotating

- Pipe Types — CS, Stainless Steels & Resin

- Pipe Lengths — Up to 6m long per spool

- International Standards — ASTM D 4895, ASTM D 3307, ASTM D4101, ASTM1545-15

- Certificates — Hydrostatic Test, DP Weld Test, Spark Test, Material Certificates

Qpex Chemical piping is used in a wide range of mineral processing and solvent extraction applications with aggressive, hot, hypersaline, and high chloride chemicals and slurries. Anti-Static carbon-filled PTFE is used for flammable solvents.

Polymer Lined Piping

Polymer lined slurry pipes are popular for tailings slurries, acidic slurry, and saline or scaling liquids.

They combine the strength of a steel pipe outer with a non-metallic inner liner that is resistant to abrasion, corrosion, and/or scale from the process fluid.

Our most popular liner material is UHMWPE – a wear resistant and smooth polymer lining that also prevents scale. Made using an interference fit process, UHMWPE liners are expansion fitted within the steel pipe to prevent uneven thermal expansion, to ensure maximum operational life.

Other liner materials include TPU, POE, Rubber, and Fluoroplastics (see page 9). Polymer lined pipes and fittings are generally supplied with prefabricated flanged ends.

Qpex Polymer Lined Pipe Specifications

- Pipe Sizes — DN15 – DN1200mm

- Pressures — Up to 35 Bar

- Fluid Temperatures — -50°C to 90°C

- Connection Types — Flange

- Pipe Lengths — Up to 20m long per spool

- Available Fittings — Elbows, Bends (all types), Tees & Reducers

- Certificates — Hydrostatic Pressure Test, Burst Test, Material Certificates

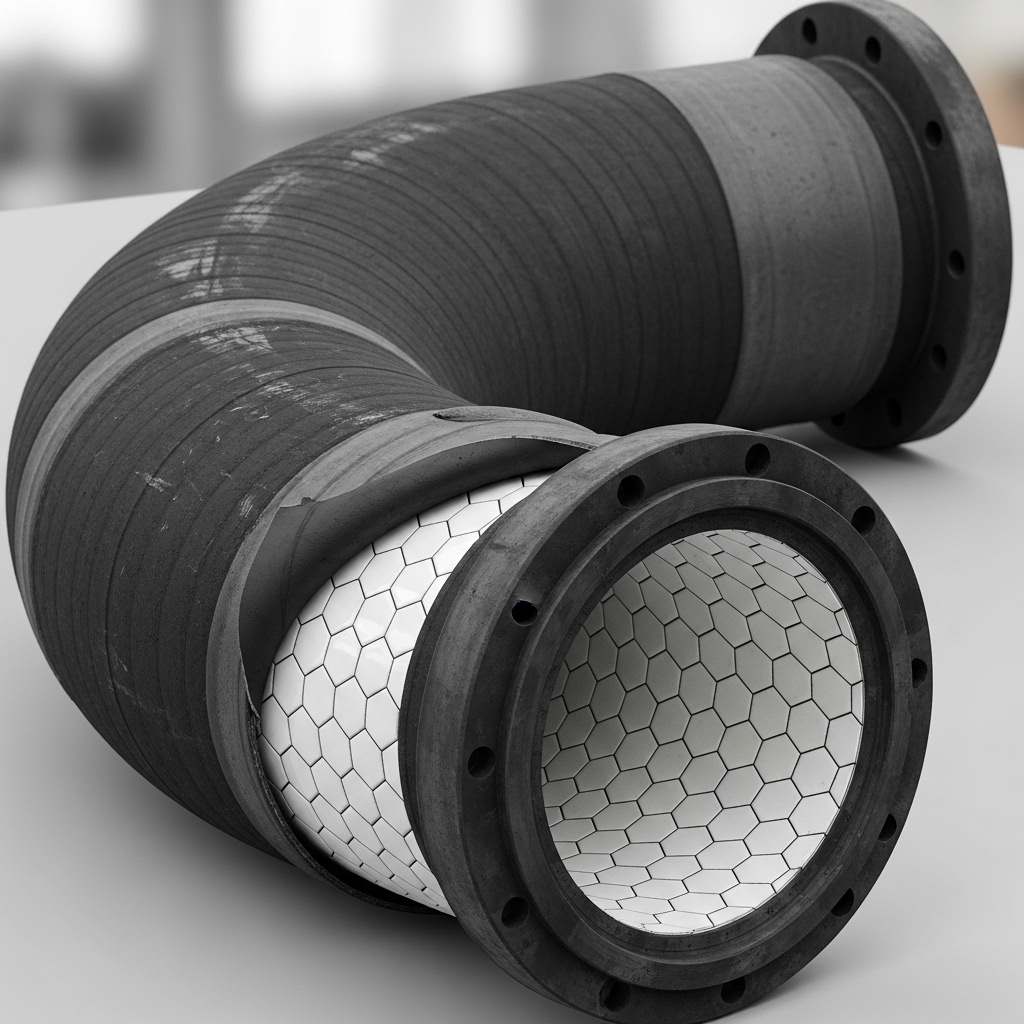

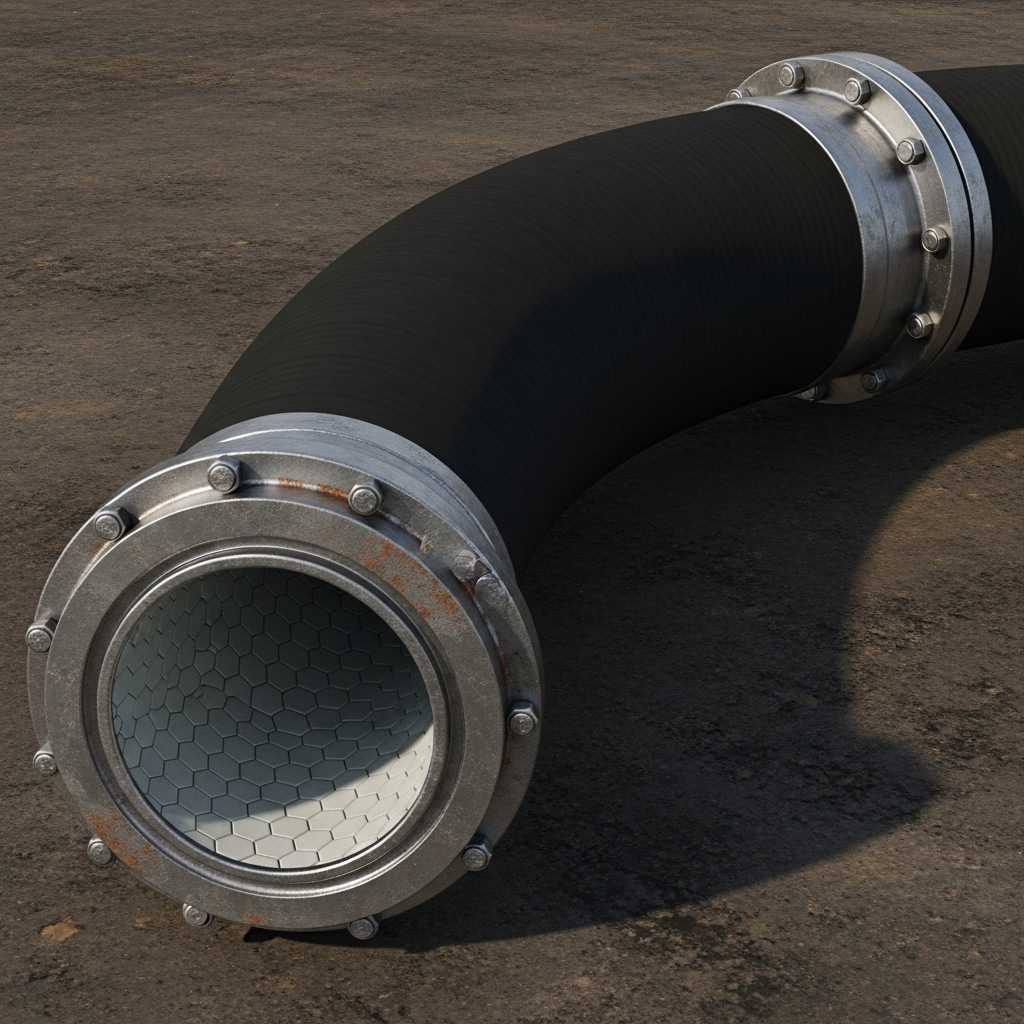

Ceramic Lined Piping

Ceramic lined pipes and rubber hoses are the toughest and longest wearing pipeline solution for extreme abrasion, coarse aggregates and high velocity slurries. They are also very resistant to corrosion, temperature, and pressure. Qpex ceramic lined pipes and hoses are used for ball mill discharge, cyclone feed, tailings, lime, high pressure paste distribution and pneumatic conveying systems.

Ceramic lined steel pipes are available with either a smooth bore internal ceramic sleeve or a tiled finish. Lining materials include high grade alumina ceramic, zirconia ceramic and silicon carbide.

Ceramic lined rubber hoses use embedded tiles to combine flexibility with extreme abrasion resistance.

These hoses are ideal for:

- Creating a sweep bend

- Accomodating pipeline missalignment

- Absorbing pipeline expansion

- Reducing transferred vibration

Qpex Ceramic Pipe Specifications

- Pipe Sizes — DN50 – DN1800mm

- Pressures — Up to 100 Bar

- Temperatures — -50°C to 900°C

- Lengths — Up to 12m per length

- Pipe Inner Material Types Available — Ceramic Tile or Ceramic Sleeve

- Pipe Outer Material — Steel Pipe

- End Connection — Flange or Coupling

Qpex Ceramic Hose Specifications

- Hose Sizes — DN50 – DN900mm

- Pressures — Up to 50 Bar

- Temperatures — -50°C to 250°C

- Lengths — Up to 6m per length

- Hose Inner Material Types Available — Ceramic Tile

- End Connection — Flange or Coupling